Lowell Sun Published May 22, 1983

by Lauren McFalls – Sun Correspondent

CHELMSFORD — Lloyd Green’s dream has yet to be realized, but the realization is well on its way.

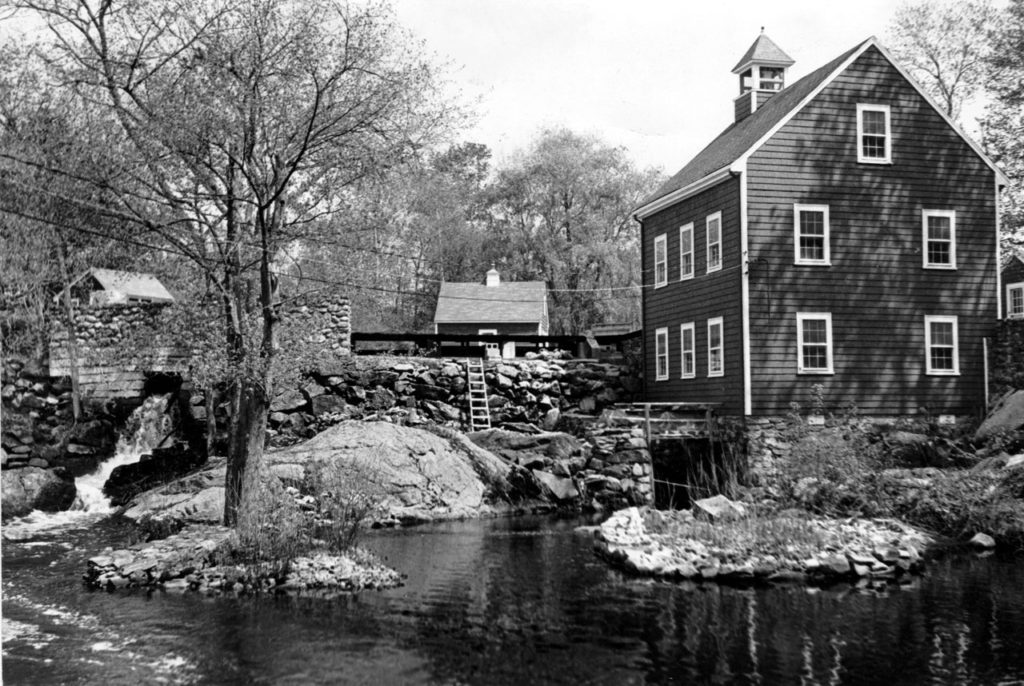

Green, owner of property and water rights at the Russell Mill Pond on Mill Road, has always wanted a little house in the country with its own generating plant

But, he isn’t building the plant simply to lower utility bills. He is building it for the charm

“When I got this place, I bought it for the old-fashioned country house with a waterwheel,” he said, and as he gazed out a window in the main house across the creek to the still watermill-less mill house

Since its conception two years ago, progress on the building of Chelmsford

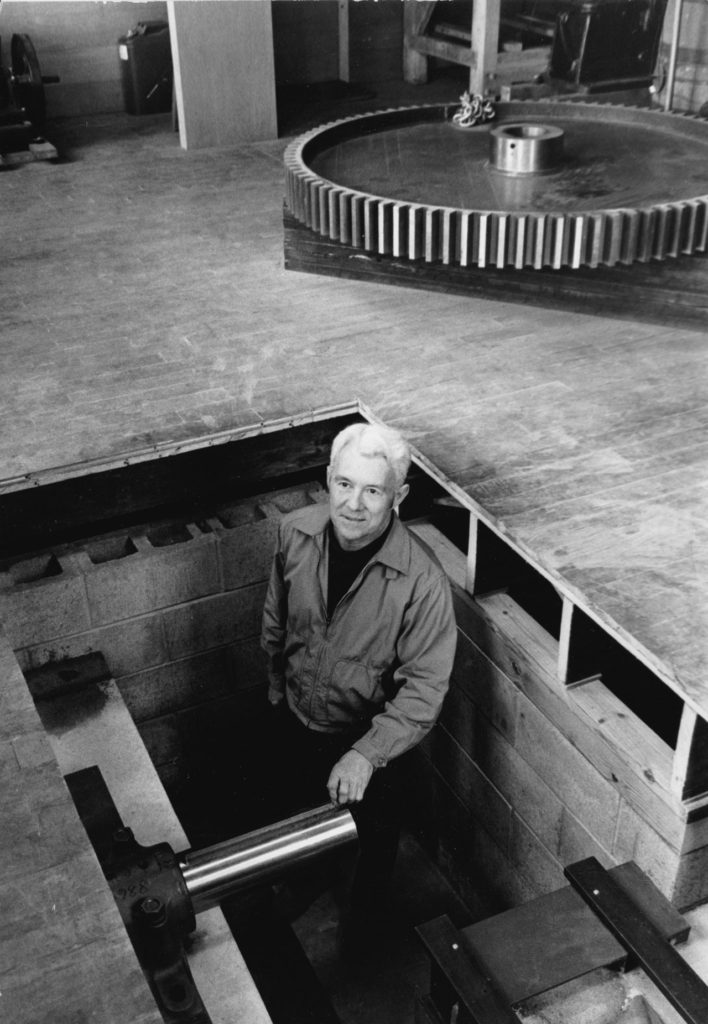

Chelmsford’s first micro hydroelectric plant at the Mill Pond has included completion of much of the supporting stonework for the wheel pit as well as the supporting concrete footings for the gear pit.

Green, owner of the property and pond water rights, started work on the plant in February, 1981.

An overshot water wheel measuring four feet in width and 12 feet in diameter will be placed in the pit and attached to the main shaft which will extend into the the gear pit located in the mill house.

A master gear will be mounted on the end of the main shaft in the house which will turn the gear box that will operate the generator.

In the mill house Green has completed concrete footings which will be used to support a 2,300-pound gear box, a 900-pound generator and a 1,100-pound main shaft.

And next week, “we’re going to murder the place in stone work,” he said, referring to stone walls that need to be built along several creek banks.

When finished the water wheel will produce 10 kilowatts per hour. A second unit to be built in the near future will generate another 10 kilowatts per hour.

Typically, a house will use five kilowatts per hour.

The water wheel, itself, is in neatly stacked pieces in the mill house. There are 16 spikes for the wheel, each with “exacting bends” which Green carefully designed in a grid for wheel builders to follow while producing the spikes.

On the other side of the room 16 rims made of copper beaming steel that Green described as “tough” lay dormant in another neat stack.

Green is building the water-mill practically single-handedly, although he does get some help from a high school student.

He has no drawn design plans for the watermill, saying that it’s all in his head.

Green is not an engineer. He’s an electronic technician who owns an educational record player and audio listening equipment company.

He said building the hydroelectric plant is a hobby, albeit an expensive one.

“I don’t take trips to Europe, I don’t smoke and I don’t drink,” and that’s how he can afford it, he said.

Sitting in a grapevine covered gazebo-like structure next to the pond, one can take in the entire panorama of the rural estate strewn with seven quaint red houses and graced with eight foot cedar trees.

“You can be transformed back into the early days,” said Green, adding that when the original mills were built on the property, in 1656, the buildings didn’t look as nice because people couldn’t afford to keep them up.

The property was originally given in the name of the King of England to Captain Samuel Adams, forerunner of the presidential family.

Subsequently, a sawmill and grist mill, two of the area’s first industrial enterprises, occupied the site.